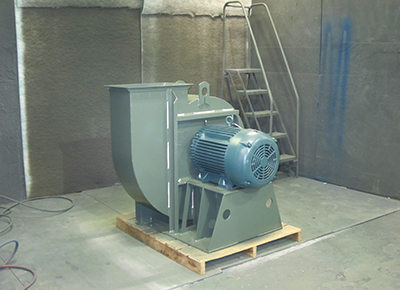

Removal of paint fumes and paint over-spray from a manufacturing area is a specialized ventilation application. The airflow volume must be low enough to not affect the application of the finishing system materials. The airflow must be great enough to remove any toxic over-spray or fumes from the workspace. This is accomplished by precise removal of air across the face of the spray booth and through the paint arresters or scrubber system. The fans must be of adequate pressure rating to overcome the spray booth and filtration losses. At the same time, the fans must be quiet enough to allow for worker exposure during a production cycle. Sometimes local codes require additional environmental systems such as solvent recovery or fume removal. These systems require additional fans that must also be selected to not contribute noise energy to the manufacturing process.

The New York Blower Company offers literally thousands of different types, models and sizes of air-movement equipment that can be customized and tailored to your specific application. See the chart below for a list of recommended fan designs, materials and features for spray booth exhaust use, or contact us to request a quote.

| Design Features: | Direct drive and belt drive are suitable |

|---|---|

| Available Materials of Construction: | Carbon Steel |

| Fan Designs: | Duct Fans |