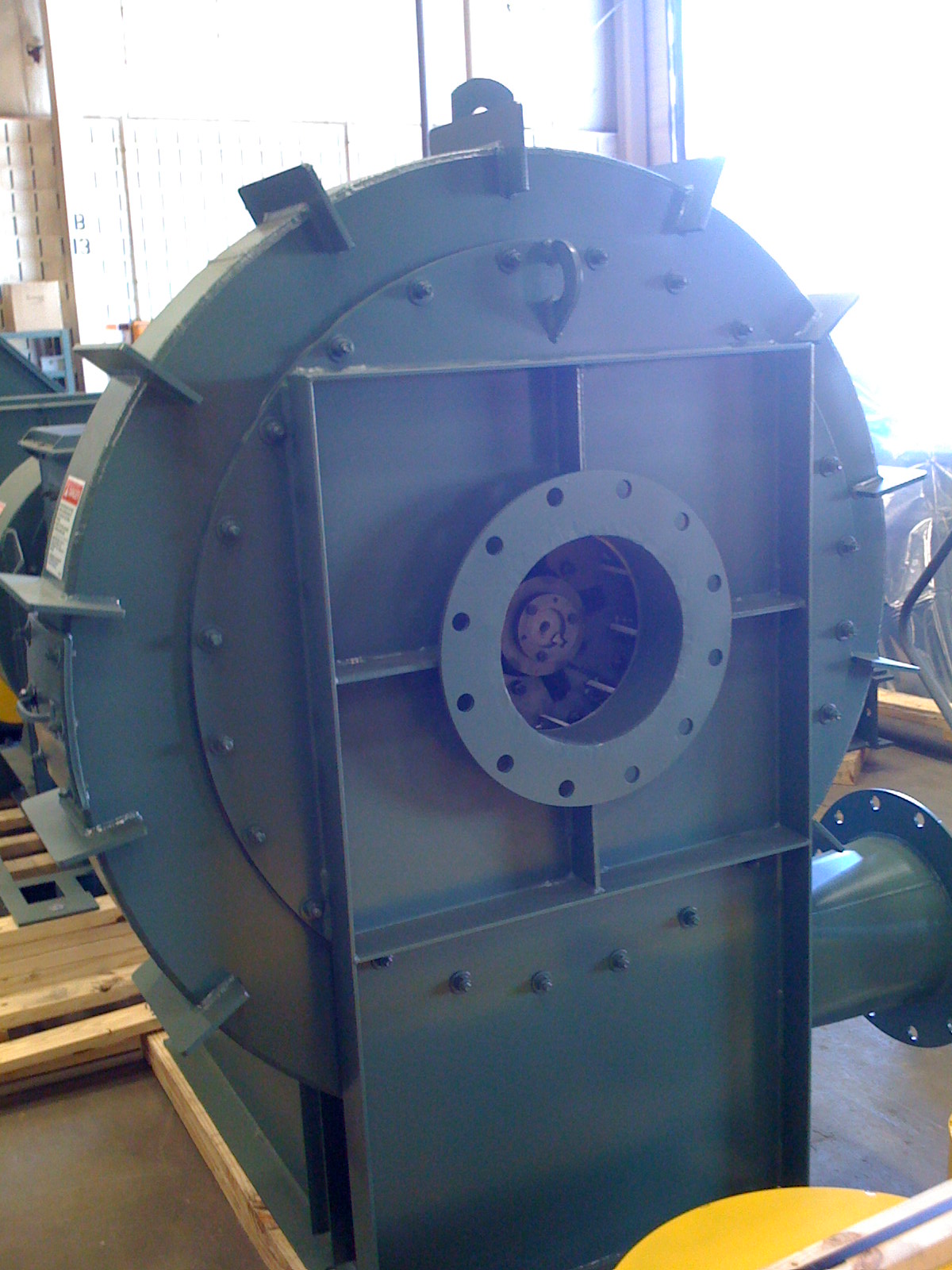

Fan applications with airstreams of explosive or flammable particles or gases require spark resistant system components for the safe handling of such airstreams. Spark Resistant Construction (SRC) is intended to minimize the potential for any two or more fan components to generate sparks within the airstream by rubbing or striking during operation. nyb can build fans to meet AMCA SRC specifications, NFPA containment standards, and ATEX requirements.

The three most common types available are AMCA A, AMCA B, and AMCA C. AMCA A (Airstream) SRC includes all airstream parts constructed of a spark-resistant alloy. AMCA B (Wheel) SRC includes the fan wheel constructed of a spark resistant alloy and a buffer plate around the housing shaft-hole opening. AMCA C (Buffer) SRC includes a spark resistant alloy buffer affixed to the housing interior adjacent to the wheel back-place, a spark resistant alloy inlet cone, and a buffer plate around the housing shaft-hole opening.

For more information on the full meaning and limits of spark resistant construction, refer to Engineering Letter 15.

The New York Blower Company offers literally thousands of different types, models and sizes of air-movement equipment that can be customized and tailored to your specific application. See the chart below for a list of recommended fan designs, materials and features for spark resistant systems, or contact us to request a quote.

| Design Features: | Fan Types: Components: |

|---|---|

| Available Materials of Construction: | Nonferrous Alloys such as: |

| Fan Designs: | Duct Fans Class I-III SWSI

|