The New York Blower Company’s FRP Radial Fume Exhauster [RFE] and FRP Pressure Blower [FPB] are designed so that all parts exposed to the airstream are constructed of high-quality corrosion-resistant fiberglass reinforced plastic. The RFE and FPB are resistant to attack from most chemicals and are ideally suited to applications in the chemical, pulp and paper, wastewater-treatment, fertilizer, pharmaceutical, and metalplating industries.

Specifically, the RFE is designed for exhausting moderate volumes of highly corrosive fumes at moderate pressures. Typical applications include laboratory fume hoods, small plating and pickling operations, etching processes, and chemical-fume scrubbers. The FPB is designed for low volumes at high pressures. Typical applications include pulp and paper processes, chemical-fume scrubbers, and soil remediation.

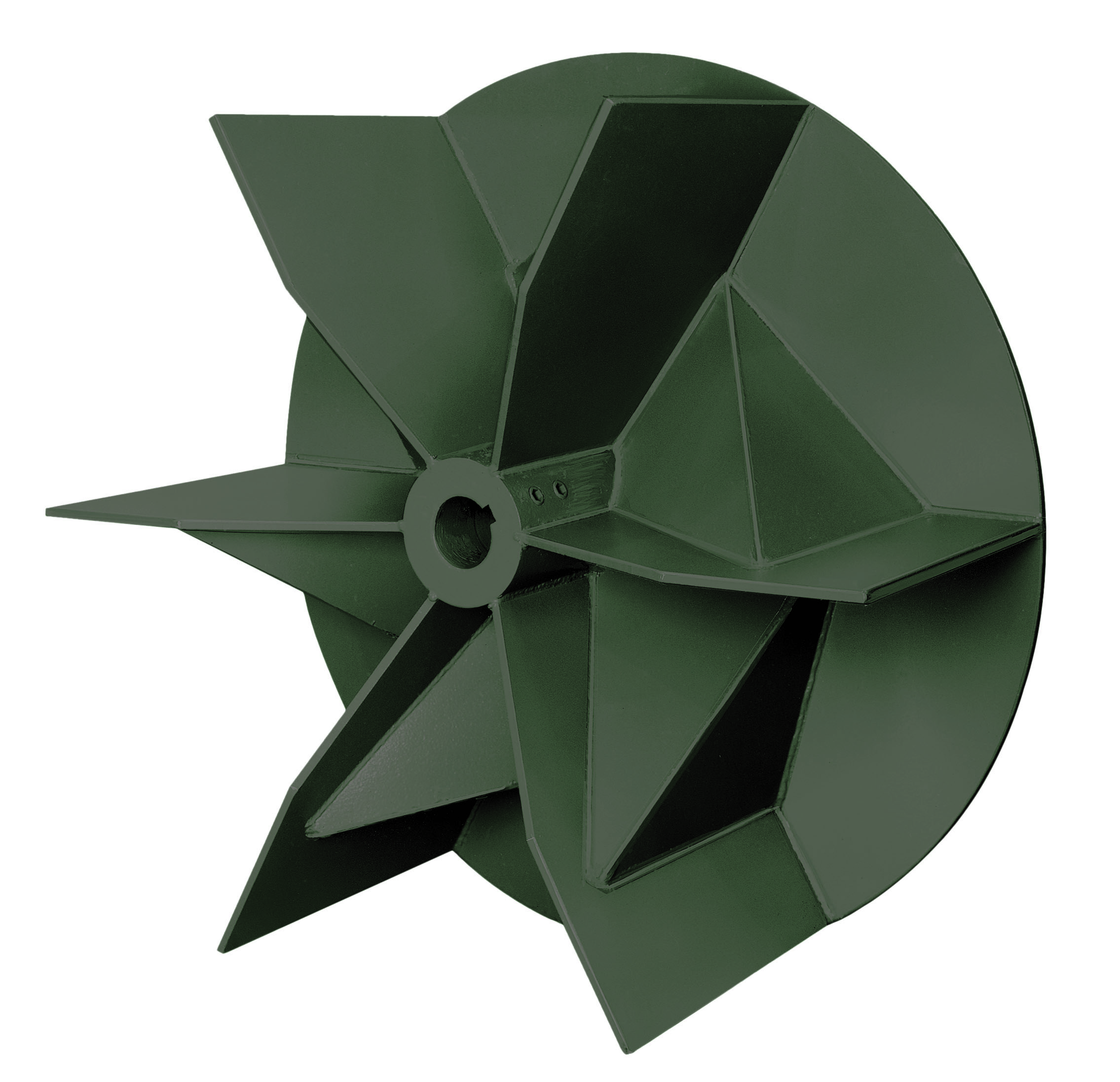

| Wheel Design: | Open Radial Radial - Modified Radial - Shrouded Wheel Radial with Backplate Radial with Backplate (Rugged Duty) Wheel Design

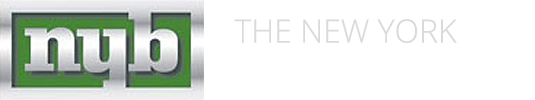

Open Radial: Straight radial wheel is ideal for both clean air and material handling applications.

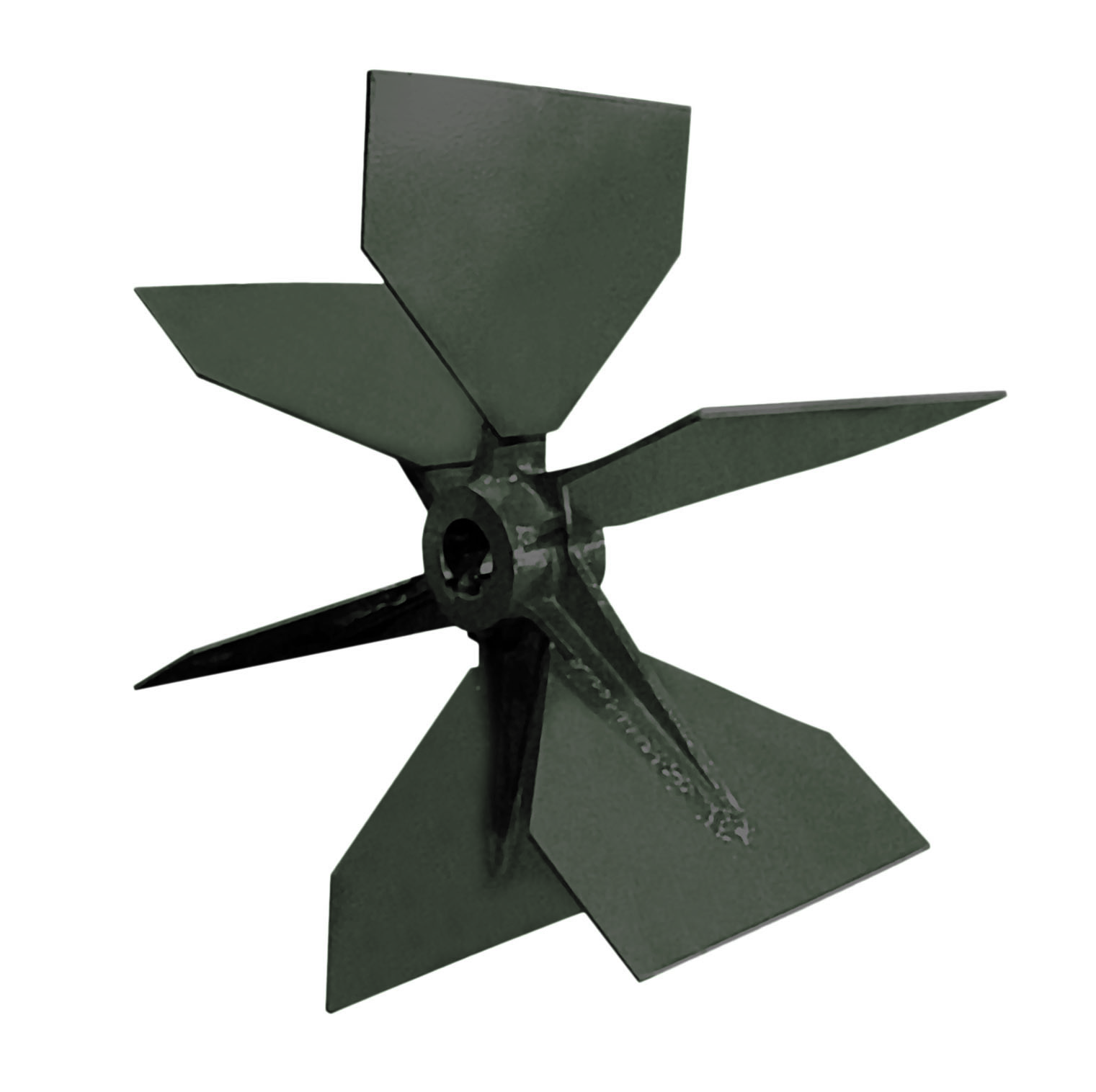

Radial - Modified: High-efficiency radial wheel with curved blades and a tapered frontplate used for airstreams with moderate dust loads.

Radial – Shrouded wheel: High efficiency shrouded wheel for low to moderate particulate applications.

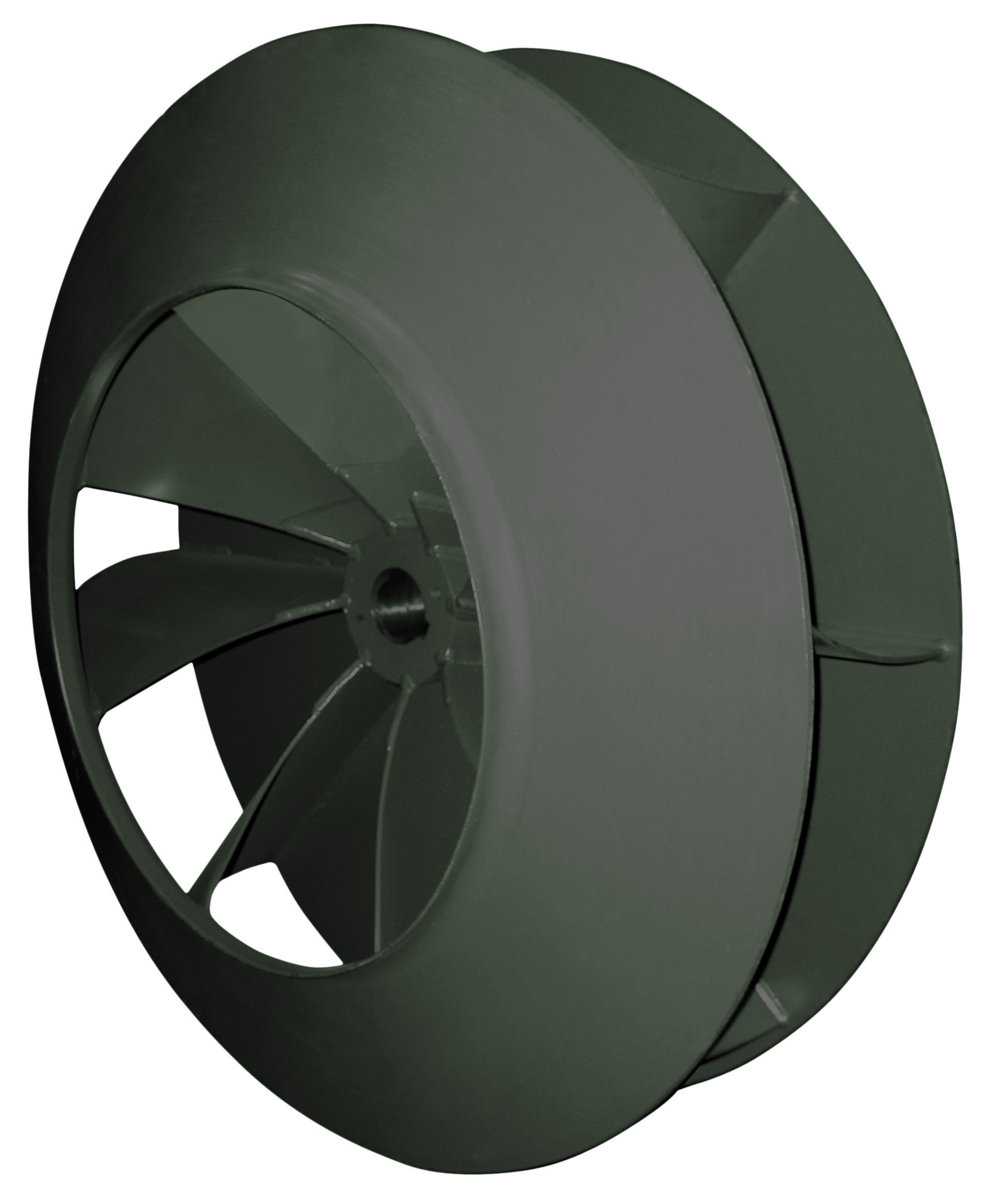

Radial – Backplated wheel: Flat radial-blade best suited for material conveying applications or those with course material.

Radial with Backplate (Rugged Duty): Heavy duty wheel designed for material handling applications involving low-density bulk materials.

|

|---|---|

| Design Features: | VOLUME - to 250,000 CFM/ 425,000 m3/hr PRESSURES - to 70" WG/ 17,400 Pa TEMPERATURES - to 800°F/ 430°C DRIVE - Belt and Direct |

| Similar Products |