In Recent News

In Recent News

The California Energy Commission (CEC) on November 16, 2022 approved the regulation of commercial and industrial fans and blowers as part of the state’s Title 20 appliance-efficiency regulations. Manufacturers of equipment covered by the regulation have until November 1, 2023, to comply.

Here’s what you need to know now.

Background

November 16, 2022 marked a new era for the commercial and industrial fan industry (fan industry). On this date, the California Energy Commission (CEC) approved the regulation of the fan industry under the Title 20 Appliance Efficiency Regulation (see Learn More). Regardless of where they are manufactured, fan shipments into the state of California are now regulated. Manufacturers are expected to comply no later than November 1, 2023.

The CEC estimates the regulation will save Californians 17 million megawatt-hours of energy or the equivalent of nearly 40 million tons of coal per year.

Potential implications exist for fans destined for the state of California at the design stage as well as the manufacturing stage of a project or order. The regulation contains three primary components: what products are covered (scope), defining acceptable operating conditions, and how the products must be labeled to clearly identify the product as certified with the State of California.

Scope

For products that meet the definition of a fan (see Learn More for a definition), the regulation applies to fans rated with at least 1-hp fan shaft power or rated with at least 1-kW electrical power but no more than 150 air horsepower. Air horsepower is defined as the energy of the air stream exiting the fan and can be calculated by multiplying the airflow by the pressure (see Learn More).

There are exceptions to the scope of the regulation that include air-curtain units, ceiling and other types of circulating fans, fans embedded in equipment performing duties other than air movement, safety fans (meeting a specified definition), crossflow fans, and induced-flow fans.

Compliant Operating Conditions

Compliant Operating Conditions are defined using two measures: a measure of energy efficiency (a metric) and a level at which the metric is acceptable. Failure to operate at this required level of energy efficiency as described by the metric results in a non-compliant condition. Products operating at non-compliant conditions are not to be offered for sale in or shipped into the State of California.

Introduction

The CEC chose the Fan Energy Index (FEI) as the metric used to regulate fan energy efficiency. FEI was developed by the Air Movement and Control Association International, Inc. (AMCA) and published as AMCA/ANSI Standard 214-21 titled "Test Procedure for Calculating Fan Energy Index (FEI) for Commercial and Industrial Fans and Blowers.” For more information on AMCA 214-21 see the Learn More section.

FEI can be best thought of as a ratio of the performance of two fan systems operating at a given duty point. The ratio is between an actual fan and a reference fan. The reference fan is a fictitious fan that operates at a minimum acceptable efficiency. To compare the performance of the two fans, the fans must be assumed to operate at the same duty point. A duty point consists of 1) a volume flow rate, 2) a pressure value, 3) a density of the fluid (typically air) being moved, and 4) the power being consumed to deliver the described flow and pressure at the given density. The better the fan system efficiency, the higher the FEI rating.

The terms fan system and fan are frequently used interchangeably. FEI is a wire-to-air metric. This means that FEI estimates the energy consumed from the point where the electricity consumption begins (often referred to as the mains) to the point where the energy is delivered in useful work (see definition of air power). Consequently, when the term fan is written, it often refers to an entire fan system.

FEI can then be expressed as the ratio of efficiencies of two fan systems. FEI = Actual Fan Efficiency/Reference Fan Efficiency

If the actual fan efficiency is greater than the reference fan efficiency, the value of FEI will be greater than 1.0 because the numerator will be greater than the denominator in the fraction. This was the primary driver for the design of FEI. The reference fan system is an imaginary fan system that operates at the minimum acceptable efficiency level for any prescribed duty point; therefore, given some reference or minimum efficiency requirement, fan systems should be designed to perform greater than the minimum requirement.

Efficient systems are important and regulatory agencies are interested in consuming less energy, which will in turn produce fewer carbon emissions. For this reason, FEI is recast in terms of power consumption as opposed to energy efficiency.

With some mathematics, FEI can be rewritten in terms of power consumption as follows: FEI = Reference Fan Electrical Power/Actual Fan Electrical Power

A good mental check is to evaluate this ratio and ensure it makes sense. If the actual fan system consumes less energy than the reference fan system, the value of FEI will be greater than 1.0. This leads to a general rule of thumb for FEI:

A fan system with an FEI value greater than 1.0 is better than a fan system with an FEI value less than 1.0.

In fact, as required by the new regulation, a fan system with an FEI value less than 1.0 cannot be offered for sale or shipped into the State of California.

The Complex Nature of Fans

Over the years of developing efficiency measures for fans, one proposal was to use the fan system efficiency as the metric and set a minimum level of fan system efficiency. For example, regulation could set the minimum fan system efficiency at 60% and eliminate from the market all the fans that were below it.

For as simple as fans seem to be, they are incredibly complex products in how they interact with other systems. One way to describe fans is they are pressure-dependent devices. As the resistance a fan works against – as expressed by pressure – changes, the performance of the fan will change. Often this performance change is dramatic. Fans also have large operating ranges with peaked, non-linear efficiency curves. With small changes in system properties, such as pressure or flow, large changes in fan efficiency can result.

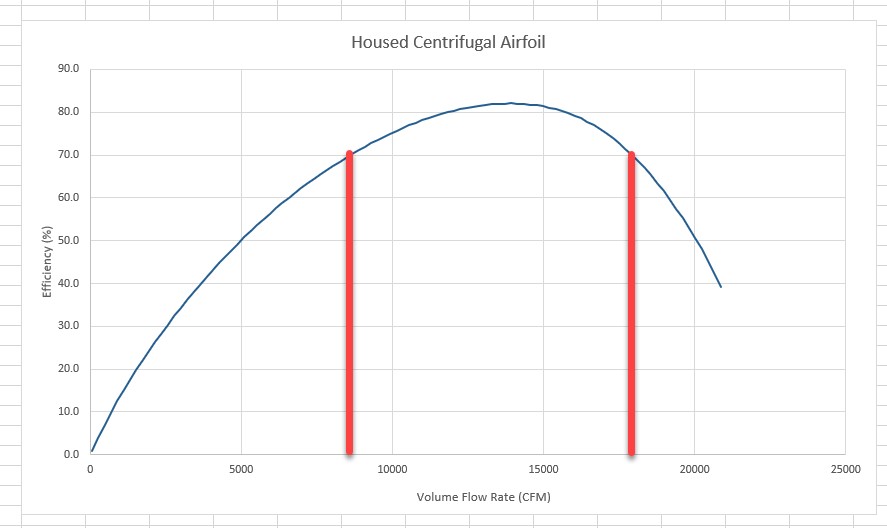

A fan efficiency curve for a centrifugal product operating at a constant speed is shown. The fan is capable of operating between zero and over 20,000 cfm (9440 l/s), but the fan only operates above 70% efficiency between approximately 8500 cfm (4010 l/s) and 18,000 cfm (8500 l/s). The fan efficiency drops quickly outside this range of volume flow rate.

A fan efficiency curve for a centrifugal product operating at a constant speed is shown. The fan is capable of operating between zero and over 20,000 cfm (9440 l/s), but the fan only operates above 70% efficiency between approximately 8500 cfm (4010 l/s) and 18,000 cfm (8500 l/s). The fan efficiency drops quickly outside this range of volume flow rate.

If this fan were applied in a system where the fan delivered 5000 cfm (2360 l/s), the efficiency of the fan would be 50%. The importance of this illustration is to understand that even though a fan may be capable of being applied in an efficient manner, the application of the fan in the fan system has a significant impact on the resulting fan system efficiency.

When developing the FEI metric, the authors attempted to incorporate both the value of selecting fans with high-efficiency capability and the impact of applying those fans in systems at a design point that will allow them to operate in an efficient manner.

The Efficiency Requirement

As of this writing, the efficiency requirement for fans sold in the State of California is for the fan to perform at an FEI value of 1.0 or greater. Fan manufacturers will be responsible for calculating FEI values for rated products. The important issue for consumers is to understand the FEI requirement and the value of a product rated FEI 1.0 or greater.

AMCA’s Certified Ratings Program (CRP) assures that a product line has been tested and rated in conformance with AMCA’s test standards and rating requirements. The AMCA CRP tests products for energy efficiency, sound, and overall performance. The program works to validate ratings through regular testing in AMCA facilities, ensuring equipment meets industry standards and performs as specified. With more than 50 different types of certifications, manufacturers and specifiers alike can have confidence in a broad range of equipment.

Labeling

The CEC regulation requires products to be certified with the state of California and that certain portions of the certified data be placed on the product in the form of a label. The label must contain the following information:

- Maximum airflow (CFM)

- Maximum fan speed (RPM)

- Maximum pressure (inches of water gauge)

- Type of pressure (“static” or “total”)

This information describes a performance envelope for the fan. If the fan operates within the stated performance envelope, it will operate in a compliant manner (FEI ≥ 1.0). Conversely, if ratings show the fan operates outside the performance envelope, it will be non-compliant.

What to do

According to Michael Ivanovich, AMCA Senior Director, Global Affairs, “The CEC regulation marks a new era for the fan industry. AMCA members worked very hard to help shape the regulation, which AMCA believes is fair, achievable, and enforceable and will result in substantial energy and carbon savings.”

The regulation attempts to remove products from the market that are incapable of performing in a compliant manner while at the same time pressing system designers to apply fans efficiently.

Manufacturers are aware of the situation and are taking action to assemble data and review products for future compliance with regulatory requirements. AMCA has provided leadership in staying on top of regulatory issues, acting as a voice for the industry as well as a trusted source of wisdom for manufacturers and customers on regulatory manners.

Anyone involved in fan systems can benefit from learning more about the CEC regulation and how it will impact system design, as well as the availability and application of products. AMCA is committed to keeping the industry up to date on regulations at both the state and federal levels. See the links below for more information.

AMCA: http://www.amca.org

Learn More

Air horsepower: “Fan output power” means the power delivered to air by the fan; it is proportional to the product of the fan airflow rate, the fan total pressure, and the compressibility coefficient as determined in accordance with the test procedure specified in California Title 20 Section 1604(d)(2).

AMCA Certified Ratings Program - https://www.amca.org/certify/#about-crp

California Title 20: https://www.energy.ca.gov/rules-and-regulations/appliance-efficiency-regulations-title-20

Fan definition: The CEC regulatory language contains several definitions related to a fan. A sampling of definitions is shown below.

“Axial-inline fan” means a fan with an axial impeller and a cylindrical housing with or without turning vanes. Inlets and outlets can optionally be ducted.

“Axial-panel fan” means a fan with an axial impeller mounted in a short housing, noncylindrical, that can be a panel, ring, or orifice plate. The housing is typically mounted to a wall separating two spaces, and the fans are used to increase the pressure across this wall. Inlets and outlets are not ducted.

“Axial power roof ventilator (PRV)” means a fan with an axial impeller and a cylindrical housing as well as a housing to prevent precipitation from entering the building with or without turning vanes used to supply or exhaust air from a building. Inlets and outlets can optionally be ducted.

“Centrifugal housed fan” means a fan with a centrifugal or mixed flow impeller in which airflow exits into a housing that is generally scroll-shaped to direct the air through a single fan outlet. Inlets and outlets can optionally be ducted. It does not include a radial impeller.

“Centrifugal unhoused fan” means a fan with a centrifugal or mix-flow impeller in which airflow enters through a panel and discharges into free space. Inlets and outlets are not ducted. This fan type also includes fan designed for use in fan arrays that have partition walls separating the fan from other fans in the array.

About the author

Mark Bublitz

Mark Bublitz, Executive Vice-President – Industry Affairs at The New York Blower Company, has over 30 years of experience in the fan industry and is highly invested in energy efficiency initiatives related to the fan industry. Mark currently serves as AMCA President for 2022 & 2023 and has chaired the AMCA 214-21 Review Committee as well as the AMCA ASRAC Committee that negotiated with the US Department of Energy since 2014.